Metal vs. Plastic Electronic Enclosures

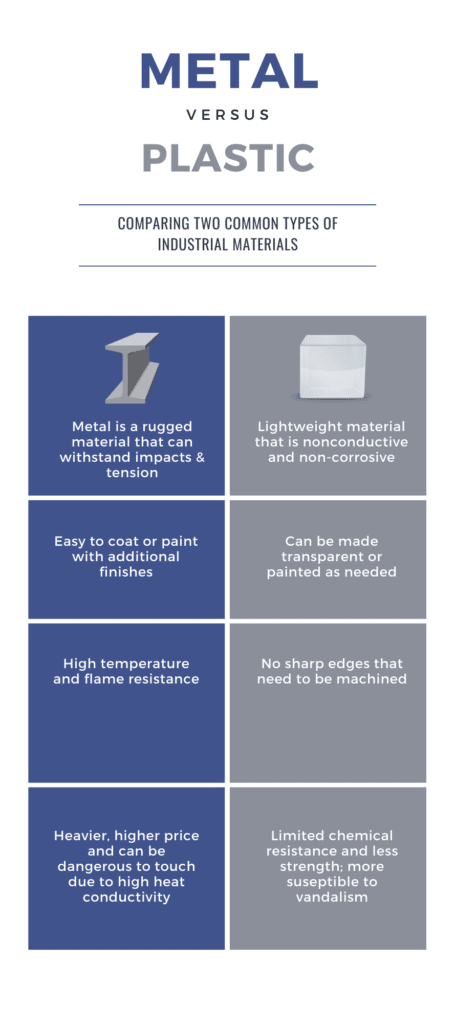

Metal and plastic are the two main categories of materials for electronic component enclosures. The better material depends on the intended application of the electronics. Whichever enclosure material you choose, safety should be the topmost consideration. The material and design of the enclosure should also be able to withstand the environmental conditions in which they will be used.

Here we’ll outline the main differences between industrial-grade plastic and metal electronic enclosures.

Pros and Cons of Metal Electronic Enclosures

Aluminum is the most common metal used to fabricate electronic enclosures. Since aluminum is nonmagnetic, it is an excellent choice for applications that require electromagnetic and radio frequency blocking. These metal enclosures enable good electrical conductivity and independent circuitry. They are also a good option in moist environments due to their corrosion resistance.

Here are other important benefits of using aluminum electronic enclosures:

- Rugged: withstands impacts and tension

- Lightweight compared to steel

- UV resistance without material additives

- Easy to coat or paint with additional finishes

- Maintains shape

- High temperature resistance

- Flame resistance

- High scrap value

On the other hand, if your application is temperature-sensitive, requires a lighter enclosure, or operates with a lower budget, metal enclosures may not be the best choice. Metal enclosures conduct heat, so they can be dangerous to touch. They also tend to be heavier and more expensive than plastic enclosures, but if these are not major concerns, metal enclosures are still preferable.

Pros and Cons of Plastic Electronic Enclosures

Plastic enclosures are constructed from electrically insulated polycarbonate, PVC, acrylics, ABS, or HIPS. Unlike aluminum enclosures, plastic enclosures allow radio and electromagnetic waves to pass through, so they are ideal for electronics that send and receive signals. Most plastic enclosures are used in indoor settings, but some polycarbonate enclosures can be designed for use outside, where they can resist harsh weather conditions.

The following are some other pros of using plastic enclosures:

- Lightweight

- Nonconductive

- Cost-effective

- Non reactive

- Non corrosive

- Can be made transparent or painted as needed

- Easy and quick to install

- No sharp edges or corners that need to be machined

Drawbacks to plastic enclosures include limited chemical resistance and less strength relative to metal enclosures. Heavy-duty applications should not utilize plastic enclosures, as they won’t stand up to sustained tension or high temperatures. They often require additional coatings, which can add to the overall cost of the enclosure. Plastic enclosures are also less resistant to vandalism and cannot be recycled as readily as metal enclosures.

Why Choose Metal Electronic Enclosures?

Aluminum electronic enclosures are superior in durability and strength under extreme conditions. The material can resist rust, flame, and UV. Aluminum is a naturally conductive metal that is excellent at shielding against electromagnetic waves and radio frequency interference. Thus, aluminum enclosures are perfect for projects involving independent circuitry and minimal interference.

Metal enclosures are also easy to paint and retain their shape over time. Typical finishes include natural aluminum, black anodized, or powder coating. Diecast metal enclosures eliminate concerns about possible seams or folds.

Aluminum Electronic Enclosures from A&J Manufacturing

The right enclosure will depend upon your application and budget. You should also consider the quantity needed and the environment for use.

Electronic enclosures are a crucial part of important electronic systems. A&J Manufacturing is a leading manufacturer of standard and custom aluminum electronic enclosures. Contact us to see how we can help with your electronics project.