Configure to Order

More affordable and readily available, modified commercial off-the-shelf (MCOTS) enclosures can reduce non-recurring engineering, unit costs, development, and production lead times. Our standard part numbers follow a key that includes height x depth/width x configuration.

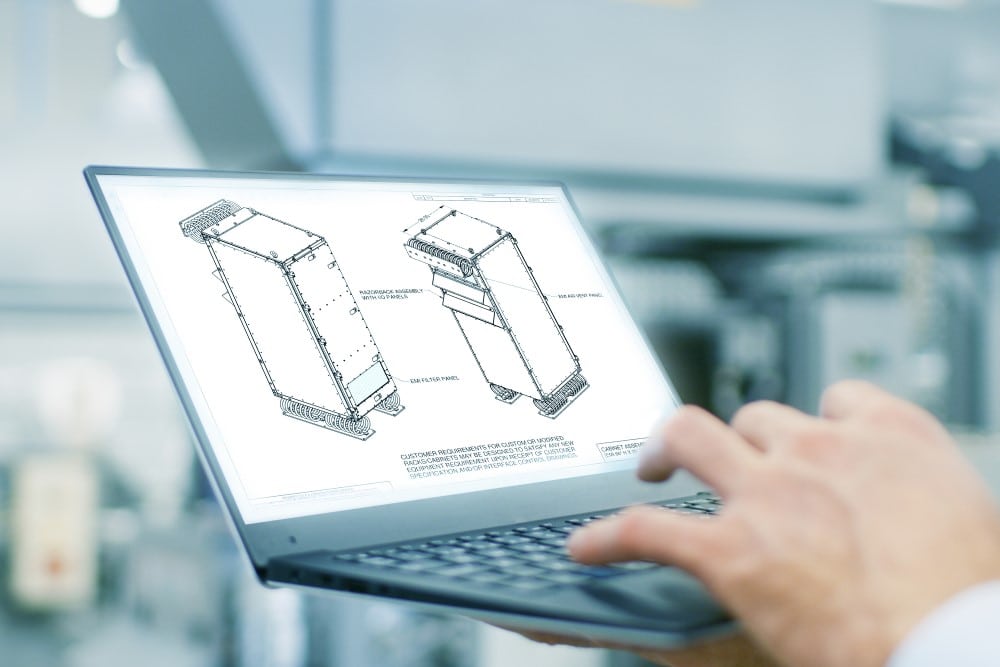

Technical Drawings

Our technical drawings complement digital CAD files, providing extra information that can’t easily be conveyed by a part’s shape alone. Our drawings might include: tolerances for specific features, geometry, dimensions, and material requirements for specific components. Download our drawings to verify crucial information.

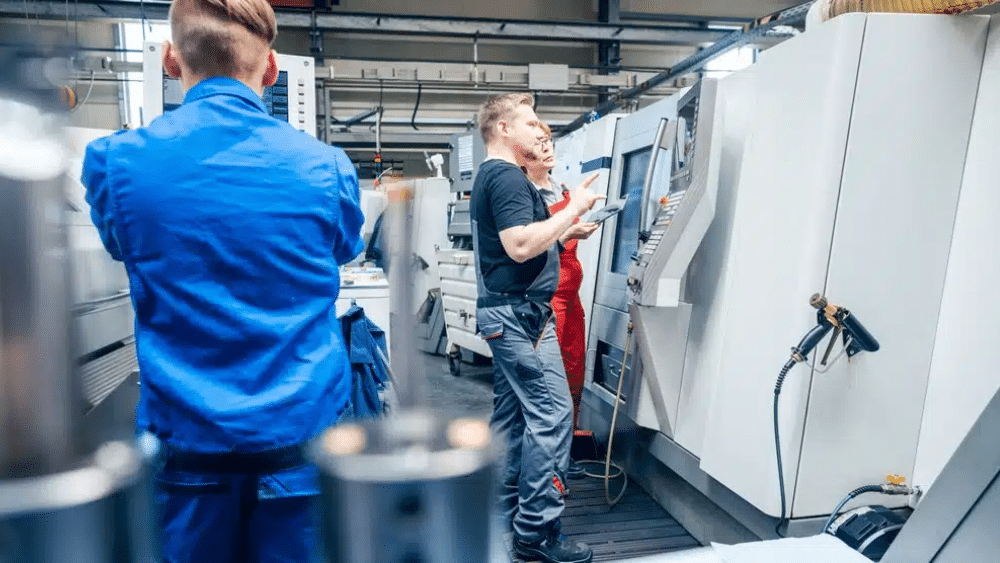

Engineering Support Services

With more than 80+ years of combined experience, our design engineers have the expertise and knowledge to customize your optimal solution. Our goal is always to meet timing, product cost, and reliability targets

Our Capabilities

Learn who we are, what we do, and how we’re different from our competitors. You can download our Capabilities Statement to include with your bid or request for proposal responses.

Frequently Asked Questions

Find answers to your questions! We’ve pulled together a general FAQ page to provide answers to several standard questions such as: product information related to our racks & enclosures or accessories & kits, our industry certifications, how we handle custom orders, how we choose suppliers, machining capabilities, and our design engineering services.

Shoptalk Blog

We’re sharing our team’s expertise and aim to provide solutions to a number of problems you might be facing as you’re pulling together requirements for your upcoming rack or enclosure design. If interested, sign up for our newsletter and we’ll email you each time a new post is published.