How to calculate temperature rise in your enclosure

When designing an electronic enclosure, temperature rise must be carefully considered to ensure all devices will function properly and for safety reasons. Heat is generated from all electronic components, and uncontrolled temperature accumulation can lead to malfunction. We’d argue it’s the most important factor to take into account when designing your rack or enclosure. The service life of components are halved and the failure rate is doubled in the event of a 10 K temperature increase.

Several ways to control temperature rise include ventilation, heat sinks, and air conditioners. By understanding how temperature rise occurs and choosing the suitable temperature control method, designers can create safe and reliable electronic enclosures.

What causes temperature rise?

Adding heat to an object or material causes the temperature to rise. The amount of heat added is determined by the surrounding environment’s temperature and the pace at which heat is generated.

Many electronic components generate heat when power flows through them.

- processors and power supplies

- semiconductor devices

- variable frequency drives (VFDs)

- programmable logic controllers (PLCs)

This heat must be dissipated to prevent the component’s temperature from rising to a level that would cause it to malfunction or fail.

It’s important to consider all these factors when calculating the rise of the enclosure’s temperature too:

- Environmental conditions outside , such as direct sunlight, can increase the internal heat load.

- Since hot air rises, many vertically mounted enclosures will be hotter at the top versus the bottom. Additionally, the overall orientation of the enclosure affects how heat dissipates. Horizontally mounted enclosures experience significantly more complex heat transfer mechanisms.

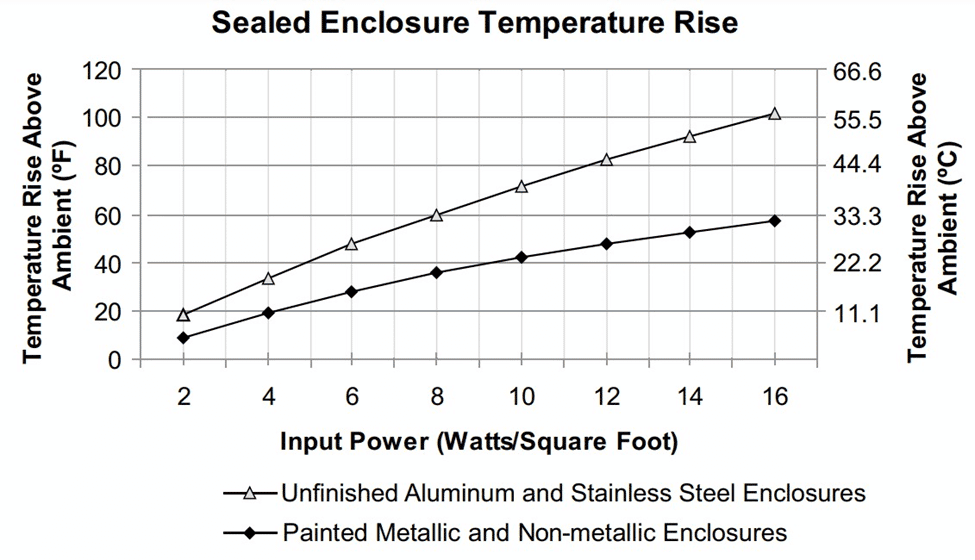

- The enclosure’s construction materials and finishes will affect heat dissipation. For example, unfinished aluminum or stainless steel doesn’t radiate heat as effectively.

How to calculate the temperature rise in an enclosure

Below is a set of steps to calculate your enclosure’s temperature rise:

- The first thing you should take action on is identifying the electrical input power indicated in watts/square foot. You can do this by taking the amount of heat dissolved within the enclosure expressed in watts and dividing it by the square feet of the enclosure’s surface area.

- Once you have the electrical input power, you can use the graph underneath to find the approximate temperature rise. To do this, locate the electrical input power at the bottom of the graph. Follow the line vertically from the point until it intersects one of the temperature curves. Use the top curve if your case is untreated aluminum or stainless steel. If your enclosure is painted metal or non-metallic, use the lower curve.

- Finally, draw a horizontal line from the intersection to the graph’s vertical axis. This will give you an estimated number of degrees that the internal temperature of the case will rise above the surrounding air temperature.

Heat Dissipation in Electrical Enclosures

(Ti-Tu) = Qv / (k*A), where

- Qv – watts to dissipate

- Tu – ambient temperature

- Ti – permitted internal temperature

- k – heat transfer coefficient

- A – enclosure surface area

By following these steps, you can better understand how much heat your electrical enclosure can safely dissipate without exceeding its temperature rating.

Tips for reducing temperature rise in your enclosure

There are several ways to reduce the amount of heat dissipated within the enclosure, such as:

- Reducing the size of the enclosure

- Using a material with high thermal conductivity

- Adding ventilation

- Adding a heat sink (ex: fins or liquid coolant)

- Adding forced air via an internal air conditioner or fans

Safely dissipate the heat generated by your electronic components

Don’t hesitate to contact us for help with your enclosure design and calculating your enclosure temperature. We have the expertise and experienced engineers to help you select the suitable size, and ventilation for your enclosure to ensure that it can safely dissipate the heat generated by your electronic components.

2 Comments

Paula Edouard

To the aj-racks.com administrator, Your posts are always thought-provoking and inspiring.

Tom

Hi,

How is it that an aluminum enclosure will have a higher temperature rise than plastic enclosure?

Aluminum has a much better heat transfer rate than plastic.