Rugged Electronic Cabinets, Racks & Enclosures – A&J Manufacturing

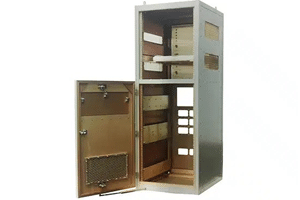

At A&J Manufacturing, we recognize that the integrity and efficiency of your electronic systems are crucial. Understanding this, our equipment rack and enclosure solutions are meticulously crafted, offering an optimal balance of robust protection and enhanced functionality for your equipment.

These solutions safeguard your systems and streamline their operation and maintenance, ensuring that your electronic assets always perform at their best. This commitment to quality and performance is at the core of everything we do, reflecting our dedication to excellence in every product we offer.

Enhanced Protection for Your Electronics

Our equipment racks and enclosures go beyond mere storage. These advanced systems are engineered to safeguard critical electronic equipment, such as data servers, radar or sonar control panels, combat systems, and communication equipment.

Constructed with superior extruded aluminum alloys, they are designed to provide tailored protection, adaptable to a wide range of applications and varying environmental conditions. This ensures that your electronics are stored and shielded, maintaining their functionality and longevity. When used with system accessories and kits, every enclosure transforms into a specialist for particular tasks.

The Flexibility of Our Modular Design

At the heart of our product line is our innovative modular enclosure framework. This design is a fusion of robust protection and adaptable flexibility, essential for the ever-changing needs of defense and industrial sectors. The modularity of our products is a key feature, allowing them to evolve effortlessly with your business needs.

This design approach not only enhances the lifespan of the racks but also significantly reduces potential costs and downtime associated with modifications and repairs. It’s a smart investment in the future of your electronic systems, providing security and adaptability in one package.

Additional Reading:

Adaptive Design for Unmatched Accessibility

Ease of access is a fundamental aspect of our design philosophy. Our racking systems feature doors and sidewalls that can be quickly and easily removed, facilitating effortless access for modifications, maintenance, or inspections. This design approach enhances the user experience, ensuring that updates or repairs can be performed with minimal hassle.

Additionally, the frame’s versatile nature supports various door configurations and the seamless integration of various accessories. This adaptability means that your racking system can efficiently evolve alongside your changing requirements, whether for upgrading equipment, reconfiguring new applications, or expanding capacity. We aim to provide a solution that meets your current needs and anticipates future demands.

Standard Racking System Features

- Material: Aluminum and aluminum alloys, boasting a high strength-to-weight ratio and excellent corrosion resistance. Ideal for marine applications. (The advantages of using aluminum)

- Payload Capacity: Ranging from 300 lbs. to 1800 lbs.

- Surface Finish/Color: Standard options include chem-film and clear coatings.

- Dimensions: From a minimum of 11.75” to a maximum of 84.73”.

- Protection: Adhering to stringent military specifications.

- Accessories: Including cable management, erecting, baying, fastening, grounding, power distribution, and more.

- Configured-to-order: a PDF download is available outlining standard specification options including side panels, doors and RETMA rail placement

Racking System Options

- Modular and Freestanding: Designed for both individual and collective setups.

- Baying Enclosure System: Ideal for larger setups requiring multiple cabinets. Enhances stability and simplifies cable management.

- Special Applications: Catering to seismic and ruggedized needs.

- Modified or Custom Solutions: Visit our Custom Enclosures page for bespoke solutions and download our Design Requirements PDF to help plan your project requirements and necessary rack features.

- Semi-Integrated/Assembled and Non-Integrated: Flexible shipping options to suit your on-site integration needs.

Your Rack Solution

Our Equipment Racks and Enclosures are not just products, they are solutions crafted to meet the ever-evolving demands of modern electronic systems. We ensure each enclosure is a specialist, transforming your space into a secure and efficient hub for your electronic needs.

AJXR 100 Series | AJM 150 Series | AJMR & AJSR 159 Series | |

Standard Sizes | Height: 72” Width: 22.31” Three (3) standard depths: 26", 30", 36" | Height: 72” Width: 22.31” Three (3) standard depths: 26", 30", 36" | Height: 72” Width: 24” Three (3) standard depths: 26", 30", 36" |

Payload | Up to 500 lbs. | Up to 1200 lbs. | Up to 1600 lbs. |

Material | 2500 Series aluminum extrusions | 6500 Series aluminum extrusions | 9000 Series aluminum extrusions |

Shock Protection | Light Duty | Medium/Heavy Duty | Extreme Heavy Duty |

Shock & Vibration Protection | Provides a lightweight, space saving rack for protection from rain, dust and surface impact | Delivers a rack with good vibration protection using shock mounts | Delivers maximum level of shock and vibration protection, including MIL-specs: MIL-STD-901D, MIL-STD-810 and MIL-STD-167 |

Uses | Semi-Fragile Medical Equipment, Radios and Amplifiers, Field Deployed Test Equipment | Industrial Applications, Military Rapid Deployment, Field-Deploy Applications, Control Consoles/Panels, Broadcast & Television Communications Equipment | Military Rapid Deployment, Memory Storage Devices, Precision Lab Equipment, Calibrated Diagnostic / Testing Gear, Aerospace Instrumentation |

Configuration | Fully configurable (COTS & customizable) | ||

Screw Size | APEX Tool Number | Torque Value (Inch-Pound) | Adhesive Type |

5/16-18 | #4 | 108 | |

1/4-20 | #3 | 52 | Loctite 242 |

10-32 | #2 | 20 |

Ready to optimize your electronic systems with our equipment racks and enclosures? Get in touch with our team for personalized assistance and expert advice.