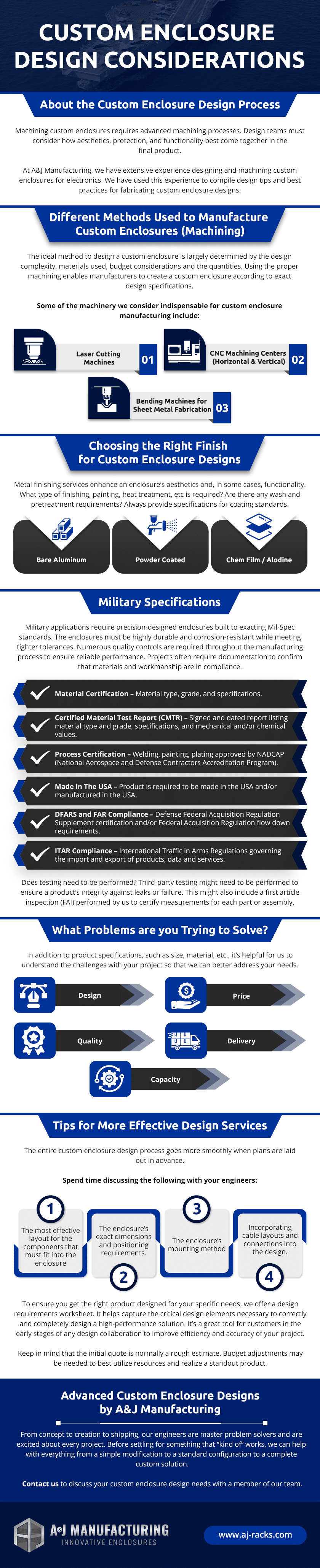

Custom Enclosure Design Considerations

About the Custom Enclosure Design Process

Machining custom enclosures requires advanced machining processes. Design teams must consider how aesthetics, protection, and functionality best come together in the final product.

At A&J Manufacturing, we have extensive experience designing and machining custom enclosures for electronics. We have used this experience to compile design tips and best practices for fabricating custom enclosure designs.

Different Methods Used to Manufacture Custom Enclosures (Machining)

The ideal method to design a custom enclosure is largely determined by the design complexity, materials used, budget considerations and the quantities. Using the proper machining enables manufacturers to create a custom enclosure according to exact design specifications. Some of the machinery we consider indispensable for custom enclosure manufacturing include:

Laser Cutting Machines

Laser cutting offers unparalleled cutting accuracy, achieving highly intricate designs every time.

CNC Machining Centers (Horizontal & Vertical)

Our CNC machines can perform several functions including: mill, drill, lathe, bore and tap.

Our Vertical CNC machining centers (VMCs) are low maintenance, but offer high functionality. They can create highly accurate cuts to exact specifications and the open view can assist in even greater attention to detail. Our operators have a greater chance of identifying imperfections and adjusting operations accordingly. These machines are extremely versatile and allow us to produce various shapes and dimensions including grooves and slots.

The Horizontal CNC machining centers (HMCs) can cut at faster speeds for better surface finishes without compromising accuracy and precision. They also have a higher table load capacity.

Bending machines for sheet metal fabrication

Custom enclosures heavily rely on various bending and forming machines during production. For instance, a coordinate measuring machine (CMM) can achieve quick and incredibly precise measurements for a true fit.

Choosing the Right Finish for Custom Enclosure Designs

Metal finishing services enhance an enclosure’s aesthetics and, in some cases, functionality. What type of finishing, painting, heat treatment, etc is required? Are there any wash and pretreatment requirements? Always provide specifications for coating standards.

- Bare Aluminum. The most affordable option, bare aluminum provides good basic corrosion resistance. Long-term use is not recommended in especially corrosive environments, such as saltwater or refineries. Such conditions can not only create unsightly discolorations but can also oxidize and damage bare aluminum enclosures.

- Powder Coated. Powder coating is extremely durable. It requires a multistage process, including cleaning and pre-treating the metal to make sure the powder adheres to the surface.

- Chem Film / Alodine. A chemical conversion coating that protects aluminum from corrosion. It’s primarily used to passivate aluminum without changing the dimensions of the parts. The most commonly used ones are MIL-DTL-5541 Type I and Type II.

Military Specifications

Military applications require precision-designed enclosures built to exacting Mil-Spec standards. The enclosures must be highly durable and corrosion-resistant while meeting tighter tolerances. Numerous quality controls are required throughout the manufacturing process to ensure reliable performance. Projects often require documentation to confirm that materials and workmanship are in compliance.

- Material certification – material type, grade, and specifications

- Certified material test report (CMTR) – signed and dated report listing material type and grade, specifications, and mechanical and/or chemical values

- Process certification – welding, painting, plating approved by NADCAP (National Aerospace and Defense Contractors Accreditation Program)

- Made in the USA – product is required to be made in the USA and/or manufactured in the USA

- DFARS and FAR compliance – Defense Federal Acquisition Regulation Supplement certification and/or Federal Acquisition Regulation flow down requirements

- ITAR compliance – International Traffic in Arms Regulations governing the import and export of products, data and services

Does testing need to be performed? Third-party testing might need to be performed to ensure a product’s integrity against leaks or failure. This might also include a first article inspection (FAI) performed by us to certify measurements for each part or assembly.

What Problems are you Trying to Solve?

In addition to product specifications, such as size, material, etc., it’s helpful for us to understand the challenges with your project so that we can better address your needs.

- Design – Are you introducing a new product and need expert engineering insights to ensure Design for Manufacturability (DfM)?

- Price – Are you looking to lower production costs on an existing product?

- Quality – Are you disappointed with another fabricator’s quality or do you need to ensure ultra-precise tolerances?

- Delivery – Are you experiencing delays from another fabricator or need a project done quickly?

- Capacity – Are you experiencing capacity issues and need to supplement another fabricator’s or your own production output?

Tips for More Effective Design Services

The entire custom enclosure design process goes more smoothly when plans are laid out in advance. Spend time discussing the following with your engineers:

- The most effective layout for the components that must fit into the enclosure

- The enclosure’s exact dimensions and positioning requirements

- The enclosure’s mounting method

- Incorporating cable layouts and connections into the design

To ensure you get the right product designed for your specific needs, we offer a design requirements worksheet. It helps capture the critical design elements necessary to correctly and completely design a high-performance solution. It’s a great tool for customers in the early stages of any design collaboration to improve efficiency and accuracy of your project.

Keep in mind that the initial quote is normally a rough estimate. Budget adjustments may be needed to best utilize resources and realize a standout product.

Advanced Custom Enclosure Designs by A&J Manufacturing

From concept to creation to shipping, our engineers are master problem solvers and are excited about every project. Before settling for something that “kind of” works, we can help with everything from a simple modification to a standard configuration to a complete custom solution.

Contact us to discuss your custom enclosure design needs with a member of our team.