One Supplier, Multiple Capabilities

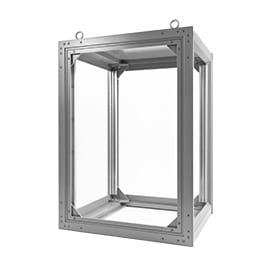

You need quality enclosures, cabinets and consoles delivered on time. You can count on A&J Manufacturing to have the in-house knowledge, experience and capabilities to deliver precisely what you need.

Our in-house capabilities include:

- Engineering

- Sheet Metal Forming and Punching

- Machining

- Assembly

- Light Integration